Industrial 4.0 technologies are redefining how factories operate, make decisions, and create value. At the core is the Industrial Internet of Things (IIoT) and its broader cousin, the IoT in manufacturing, connecting machines, sensors, and systems to gather data, drive insights, and automate actions. A smart factory built on these foundations delivers higher uptime, better quality, and more flexible production that can respond to demand in near real time, enabling predictive maintenance and the use of digital twin models to simulate, test, and optimize operations without interrupting current production. Together, these capabilities form a connected data fabric that supports advanced analytics, autonomous control, cross-functional collaboration, and continuous improvement across the entire value chain—from procurement to production, quality, and delivery. In short, Industrial 4.0 technologies are not one invention but a constellation of interoperable tools that empower a resilient, data-driven production environment capable of rapid adaptation, sustainable performance, and competitive advantage.

A complementary lens highlights connected manufacturing ecosystems, cyber-physical systems, and intelligent automation as the heartbeat of modern production. Alternative terms such as smart manufacturing, digitized operations, and data-driven production reflect the same shift, enabling real-time monitoring, advanced analytics, and autonomous optimization. When viewed through an LSI-inspired vocabulary, IIoT-driven platforms, edge-to-cloud architectures, digital twins, and advanced sensors form an integrated, resilient fabric that powers efficiency and adaptability. In practice, this reframing helps content connect to related topics like IIoT, smart factory concepts, and predictive maintenance without overusing a single label.

Industrial 4.0 Technologies: Building a Smart Factory Ecosystem with IIoT and Digital Twins

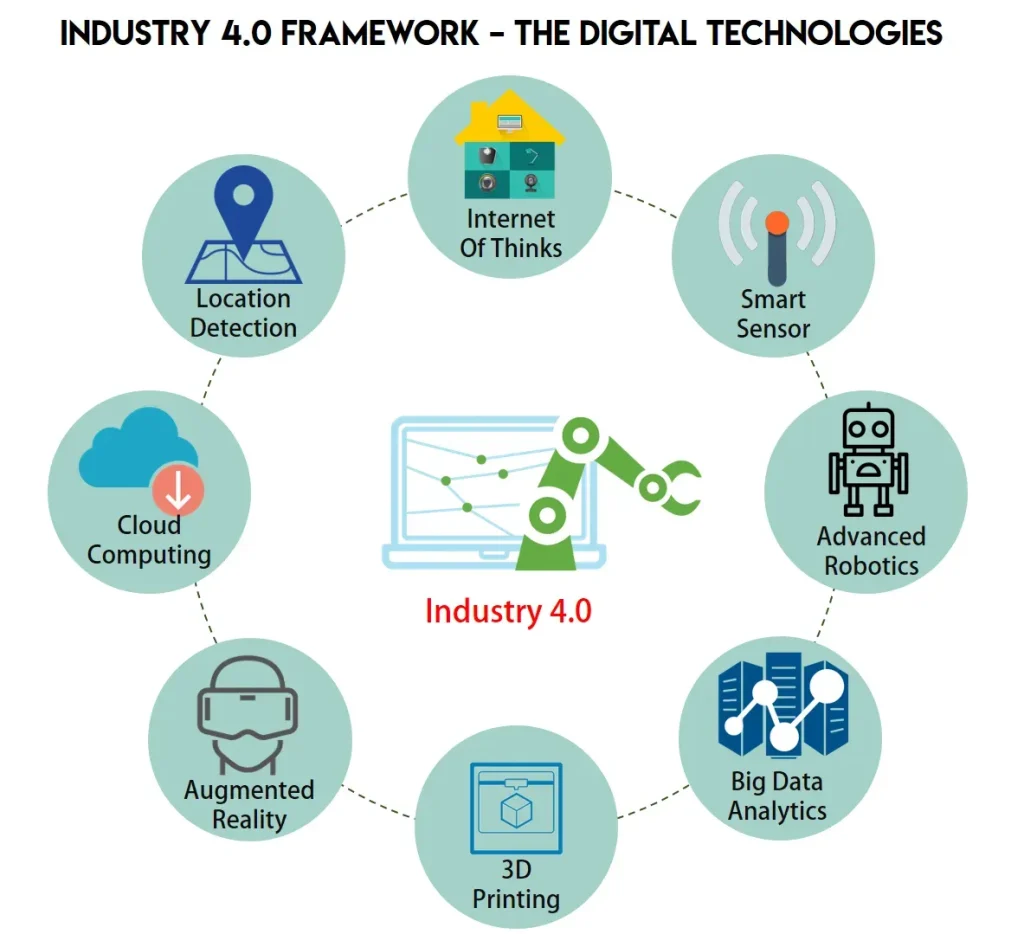

Industrial 4.0 technologies represent a constellation of digital capabilities that turn traditional production lines into intelligent, interconnected systems. The heart of this shift is the Industrial Internet of Things (IIoT) and its broader cousin, the IoT in manufacturing, which connect machines, sensors, and control systems to collect data, enable real-time visibility, and automate decision-making. In a smart factory, this sensor-driven backbone supports predictive maintenance, process optimization, and tighter quality control by turning diverse devices into an interoperable data fabric that powers analytics and automation.

A practical marriage of edge computing and cloud platforms balances speed and scale. Edge processing lets time-sensitive insights trigger immediate actions on the line, while cloud analytics store long-term historic data, enable enterprise dashboards, and support AI-driven optimization. Digital twins mirror assets and processes, allowing safe simulations, what-if analyses, and proactive planning. When these components converge—IIoT, digital twins, AI, and robotics—manufacturing becomes a resilient, data-driven operating model that improves uptime and adaptability.

Predictive Maintenance, Quality, and Efficiency Through IIoT and Digital Twins

Predictive maintenance uses continuous sensor data such as vibration, temperature, and lubrication flow to forecast component wear and schedule service before failures disrupt production. By linking equipment telemetry with historical performance, digital twins provide scenario testing and optimization of maintenance windows, reducing unplanned downtime and extending asset life. This data-driven approach aligns with the broader Industrial IoT strategy, turning maintenance from a cost center into a value driver.

Quality assurance benefits from continuous monitoring of dimensions, surface finish, and process parameters. AI-driven analytics detect deviations early and adjust settings automatically, while digital twins simulate line performance to optimize yields and minimize scrap. This focus on data-driven control complements energy optimization and sustainability efforts, delivering a smarter, safer, and more efficient manufacturing environment.

Frequently Asked Questions

How do Industrial IoT (IIoT) and digital twin technologies empower predictive maintenance in a smart factory?

Industrial IoT (IIoT) connects sensors and machines across a smart factory to stream real-time data (IoT in manufacturing). A digital twin creates a live virtual model of the asset, uses current data to simulate performance, and predicts wear or failure, powering predictive maintenance. In a connected plant, this closed loop reduces unplanned downtime, optimizes maintenance timing, and improves asset health and overall efficiency.

What role does IoT in manufacturing play in achieving real-time visibility and efficiency in a smart factory, especially with digital twins and predictive maintenance?

IoT in manufacturing streams performance data from equipment to edge and cloud analytics, delivering real-time visibility across operations in a smart factory. Digital twins use that data to model processes, run what-if analyses, and detect anomalies, enabling proactive optimization. When combined with predictive maintenance, this approach reduces downtime, lowers costs, and improves quality and reliability.

| Topic | Key Points | Notes / Examples |

|---|---|---|

| IoT and IIoT | Sensor-driven backbone; IoT connects sensors, devices, and machines in manufacturing; IIoT adds industry-specific protocols, reliability, and security at scale; enables predictive maintenance, process optimization, and tighter quality control by turning disparate devices into an interoperable data fabric. | Interoperable data fabric for analytics and automation. |

| Edge computing and cloud | Edge processes latency-sensitive data near the source for real-time alerts and control; Cloud consolidates data from multiple plants, runs heavy analytics, stores long-term history, and supports dashboards; combined edge+cloud balances speed and scale. | Real-time decisions at the edge with scalable analytics in the cloud. |

| Digital twins and virtual models | A digital twin is a dynamic virtual replica that mirrors real-time data, runs simulations, and tests changes without disrupting production; enables scenario planning, process optimization, proactive maintenance, and a single view of machine health, status, and energy use. | Scenario planning and what-if analyses to optimize operations. |

| Artificial intelligence and machine learning | AI/ML interpret large sensor data streams to power predictive maintenance, anomaly detection, quality prediction, and parameter optimization across lines; models forecast wear, detect subtle deviations, and automatically adjust tuning. | Automated tuning keeps processes within spec. |

| Automation, robotics, and control systems | Automation and robotics have evolved to collaborative systems guided by AI; robots work with humans, perform repetitive tasks precisely, freeing humans for problem-solving; integrated with IIoT data and digital twins for a closed-loop system. | Closed-loop optimization for throughput and reliability. |

| Connectivity, standards, and cybersecurity | Robust industrial networks (5G/private LTE) provide bandwidth and real-time data sharing; interoperability standards and APIs enable vendor diversity; security is essential (encryption, access control, threat detection, secure updates). | Secure, scalable data exchange across heterogeneous systems. |

| Use cases: Predictive maintenance and asset optimization | Predictive maintenance correlates telemetry with history to predict failures, reduce downtime, and extend asset life; example includes vibration, temperature, and lubricant data feeding predictive models. | Plan downtime and optimize maintenance scheduling. |

| Quality assurance via data-driven control | Sensors monitor dimensions and quality metrics; AI analytics detect deviations and adjust parameters; digital twins simulate what-if scenarios to tune machines for yield, reduce scrap, and speed product introductions. | Quality improvements through real-time analytics. |

| Energy optimization and environmental impact | Track energy use at machine/line level; analyze patterns to reduce peak demand, optimize pumps/compressors, and schedule energy-intensive tasks for cheaper windows; improves cost and sustainability metrics. | Lower energy costs and greener production. |

| Supply chain visibility and resilience | IoT + ERP/PLM enable end-to-end visibility of inventory, production progress, and delivery status; digital twins model supply chain scenarios to support resilient decision-making. | Real-time planning and disruption response. |

| Workforce enablement and safety | AR tools, hands-free guidance, and remote monitoring empower workers; contextual information reduces training time and errors; safety systems with sensors/AI detect hazards and trigger alerts. | Improved productivity and safer operations. |

| Challenges: Legacy equipment and integration friction | Legacy assets not designed to share data; bridging with sensors, gateways, and APIs requires governance to minimize risk and downtime. | Plan phased integration and governance. |

| Interoperability and standards | Diverse vendors and protocols require compatible platforms; open standards and API-first approaches help, with ongoing evaluation as tech evolves. | Set governance for data exchange. |

| Cybersecurity and data protection | Attack surface grows with connectivity; security must be embedded across layers: device auth, encryption, threat detection, secure updates; regular security assessments and cyber hygiene are essential. | Security-by-design in every layer. |

| People, processes, and skills | New skills in data analytics, cloud/edge architectures, and change management; invest in training, redefine roles, and foster cross-functional collaboration between operations, IT, and engineering. | Workforce development drives adoption. |

| Practical roadmap for adopting Industrial 4.0 technologies | 1) Start with a clear business case; 2) Build the data foundation; 3) Deploy edge and cloud; 4) Introduce digital twins and AI; 5) Scale responsibly; 6) Sustain the transformation. | Structured steps to guide adoption. |

| Conclusion (embedded in table) | Industrial 4.0 technologies lay the groundwork for a data-driven, proactive manufacturing future where IIoT, IoT in manufacturing, digital twins, and predictive maintenance work together to optimize production. | End-to-table note. |

Summary

Below is an HTML table explaining the key points from the provided base content, followed by a descriptive conclusion about Industrial 4.0 technologies.